Activities

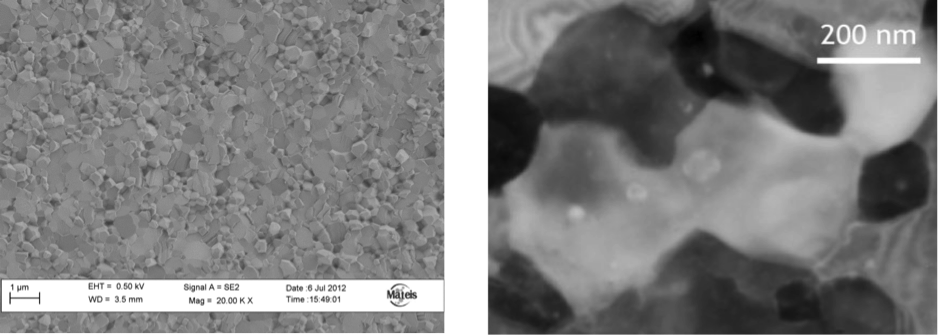

Creating and producing materials is crucial and the laboratory’s activity is very dependent on this step. It has developed its technical and scientific potential in creating and producing thermomechanical treatments that allow us to alter the material. Equipment such as the SPS machine or the Gleeble quick thermomechanical treatment machine enable us today to develop materials and multimaterials presenting particular microstructures (and therefore properties) and which open up to new applications. Studies on creating and producing specific materials such as nanostructured ceramics or ultra fine grain metallic materials are conducted in conjunction with using this equipment. (cf. figure below).

On the left: Transparent aluminium oxide – grain size 290 ± 40 nm obtained by FAST/SPS sintering. On the right : Pure iron – sub-micronic grain size obtained by spark plasma sintering

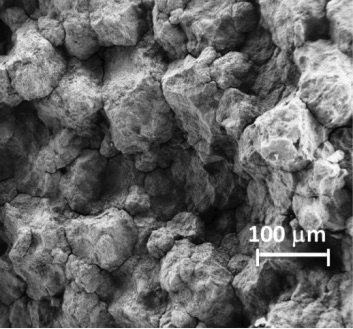

Moreover, the laboratory develops specific sintering measures for obtaining, for example, polymers with a high molecular mass. The main feature of sintering polymers is that the compaction phase leads to a density that is almost equal to 1 (cf. figure below).

Polymer sintering using the Gleeble machine.

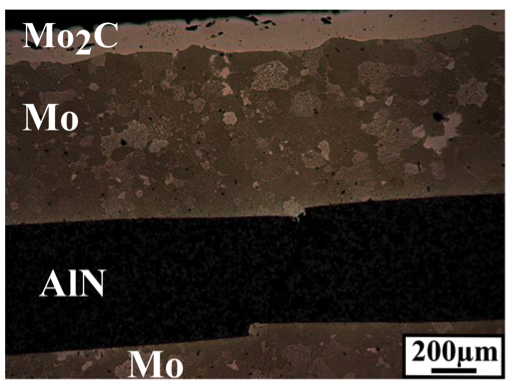

The difficulty lies in the chain diffusion (very slow) and their re-entaglement to form a resistant interface. Other studies also aim to produce architectured or non-architectured composite materials (cf. figure below).

Multilayer Mo/AIN/mo.

MATEIS undertakes studies that compare different sintering methods in order to better understand the advantages and disadvantages of each technique by researching the mechanisms brought into play.