Teams

Contact : Dr. Sylvain Dancette

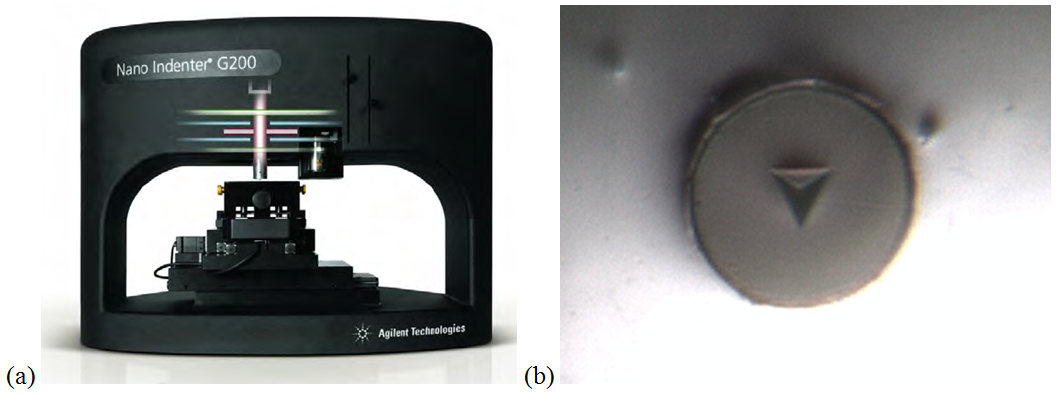

The G200 Agilent nanoindenter allows indentation down to the nanoscale. It is typically used to measure local elastic moduli, hardness, toughness and damping coefficients or to perform scratch tests. The indent depths starts from few nm up to several μm below the surface with an indent position accuracy of about 1 μm. The G200 Agilent nanoindenter owns the Continuous Stiffnes Measurement module (CSM) that allows continous measurements during indentation as well as the High Load module including load up to 1 Kg. Several tips as Berkovich, Vickers, Cube corner, spherical and flat punch are available.

The G200 Agilent nanoindenter setupe has been developped in January 2012 with the financial support of both the MATEIS laboratory and the Carnot institute @ Lyon. It is currently used by all the MATEIS research groups on several materials classes: ceramics, metallic alloys and composites, biomaterials, thin films, porous and architectured materials, etc.

Fig. 1 (a) The G200 Agilent nanoindenter (b) Indentation within an inclusion of a composite materials (A. Ferré, "Élaboration et caractérisation 3D de l’endommagement dans les composites amorphe-cristallins métalliques", Ph.D thesis, Materials Engineering department, INSA-Lyon).