Means of mechanical characterisation and examples

The group’s mechanical activity supports several of the laboratory’s main themes:

- - Behaviour of dense ceramics at the cracking phase (notched flexure testing, double-torsion testing) – diagrams v-KI

- - Mechanical behaviour at temperature of ceramics and composites (tests up to 2000°C, traction, compression and flexure) together with a study of acoustic emission signals (see the transversal activity description - Composites)

The past few years, an effort has been made to develop new characterisation methods to add to the group’s strong points. These developments have been implemented on highly porous ceramics.

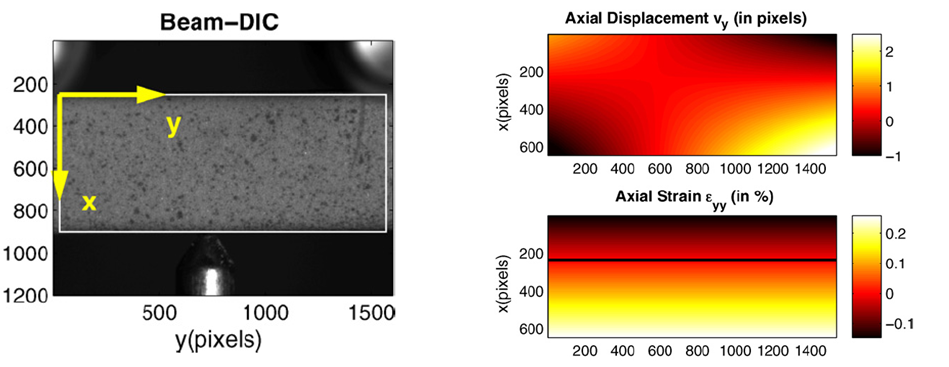

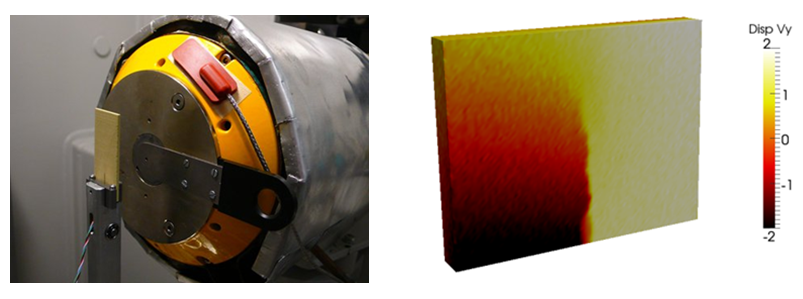

- - Image tracking enables us to determine the deformation field under stress and potentially identify a mechanical behaviour law (thesis by Paul Leplay in collaboration with the LaMCoS laboratory). This method has also been implemented in high temperature tests.

Sample tested during a four point flexural test and displacement and flexural deformation circuit cards determined by digital image correlation, , P. Leplay et al, Journal of the European Ceramic Society, 30 (13), pp. 2715-25, 2010

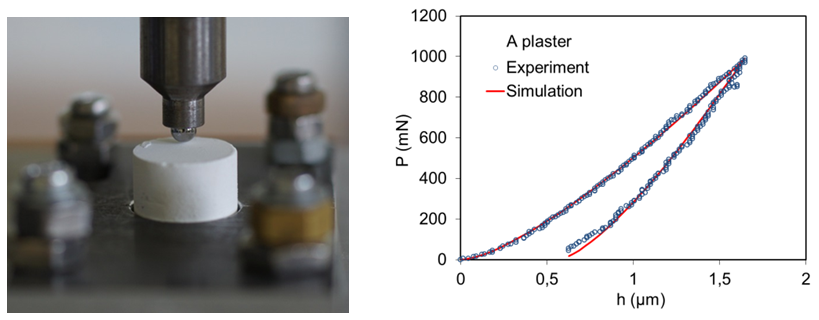

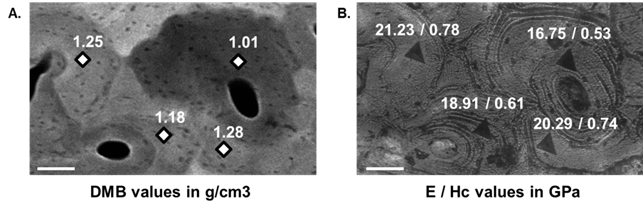

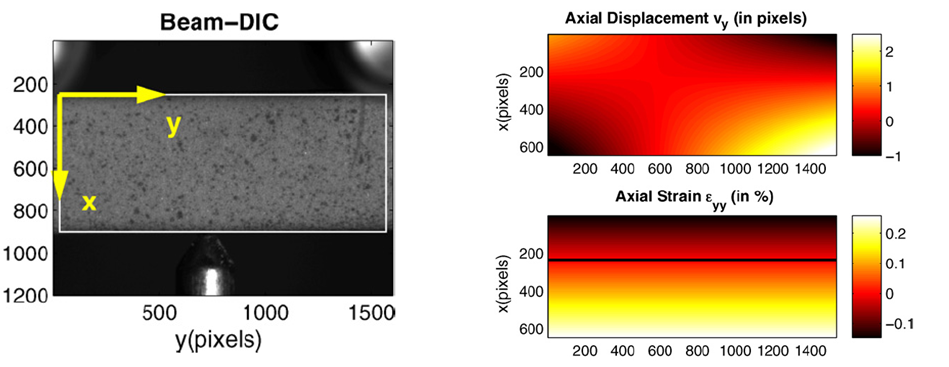

- Instrumented indentation enables us to characterise the local properties of a material and to identify a behavioural law (Philippe Clément’s thesis on porous ceramics for bone substitutes). Bone tissue characterisation is also carried out in collaboration with the LYOS INSERM laboratory.

Plaster indenter densification, spherical indentation curves by experiment and finite element simulation, P. Clément et al, Acta Materiala, 2013

Correlation between the mineral bone density measured by X-ray radiography (on the left) and the elastic module and hardness determined by indentation (on the right), human bone tissue, Y. Bala et al, Journal of the Mechanical Behaviour of Biomedical Materials, n°4, pp. 1473-1482, 2011

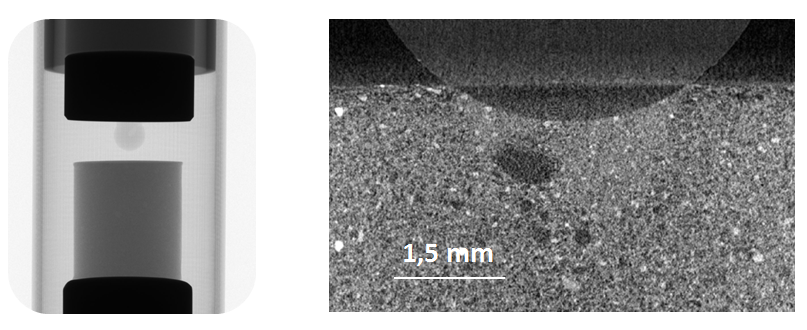

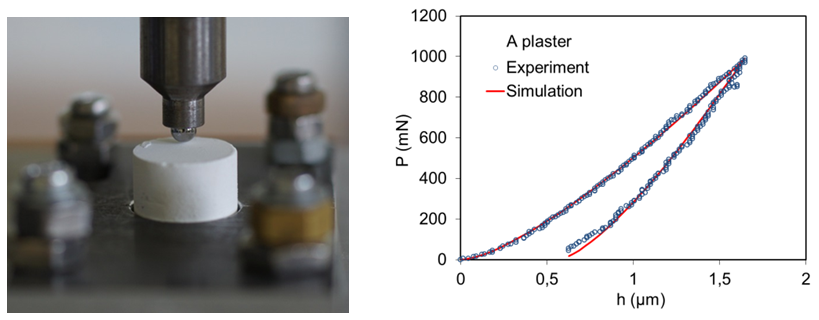

- In situ tomographic testing in collaboration with the Metal Group (Eric Maire and Jérôme Adrien): developing double torsion prototypes, instrumented indentation and heating. Test analysis possible with 3D image correlation (collaboration with Julien Réthoré LaMCoS).

X-ray tomography in situ indentation testing - Observation of plaster densification taken during in situ indentation (20 N applied, 6 mm sphere) thesis by P. Clément 2013

Prototype of an in situ double torsion test using X-ray tomography , displacement analysis using image correlation, P. Leplay et al, Experimental Mechanics, 2013